From “Never Build” to “New Beginnings”

May 15, 2025Finally Done!

After months of meticulous planning, countless hours of hard work, and overcoming numerous bureaucratic hurdles, our pioneering construction project—built entirely from reused rails— stands proudly completed. Not only does it represent an architectural and environmental milestone, but it also symbolizes that ecological responsibility can align with economic benefit.

But lets start at the Beginning

When ETH MAS Architect Dimitri Durst first explored reusing old railway tracks in architecture, the concept was met with skepticism. Yet Dimitri saw potential where others saw scrap. Driven by the ETH ethos of innovation, he set out to prove that used rails could find new life in sustainable construction. After a one year long feasibility study in 2023, uncertainty transformed into excitement. Dimitri has proven together with Weber+Brönnimann AG that rails—high quality steel designed for heavy loads—are structurally reliable even after their primary use, paving the way for something groundbreaking.

Turning Plans into Reality

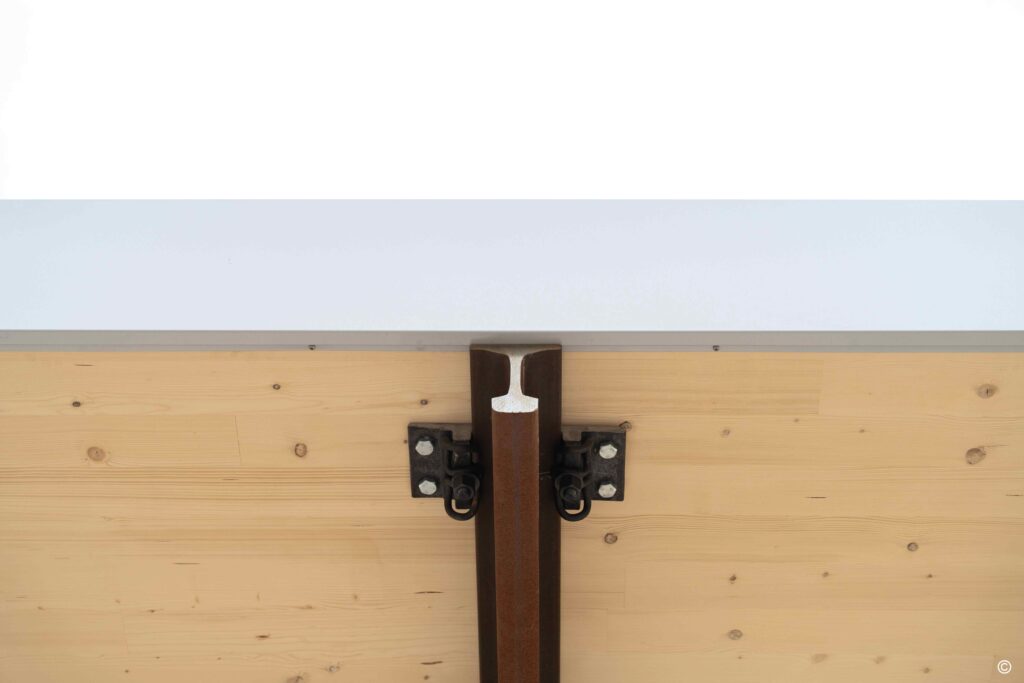

With structural doubts resolved, Dimitri faced the next challenge: finding suitable ground to build. Essential partnerships with SBB Resale and the Bahntechnik Center Hägendorf opened doors, providing a perfect site— covering e-car parking spaces. Navigating bureaucracy and patenting Arrangement and details of all innovations along the way proved lengthy but necessary steps, safeguarding his pioneering idea and investments. As Dimitri moved into production, another innovation emerged: using screws instead of welding. The pre-production phase initially seemed unconventional, yet steel constructors found minimal adjustments necessary, highlighting the project’s feasibility. Each step reinforced Dimitri’s conviction: sustainable innovation isn’t merely idealistic—it’s entirely practical.

Rails Up: The Sustainable Construction Begins

Finally, construction day arrived. Starting with a solid yet simple foundation, the reused rails went up swiftly, as straightforward as conventional steel structures, thanks to the innovative

screw method. The structure’s strength became dramatically evident when four large Cross-Laminated Timber (CLT) panels were placed confidently atop the rail frame, demonstrating

strength without additional beams. With final touches like floor cleaning and precise marking of parking spots, the construction site transformed from a challenging experiment into a compelling example of sustainable architecture. Dimitri’s vision—once uncertain—stood firmly, a proud landmark of innovative reuse.

Results That Speak Volumes

With the project complete, results exceeded every expectation:

- Structural excellence: Effortlessly carrying a roof load exceeding 15 tons.

- Durable and robust: Easily handling extreme conditions, including open-field winds of up to 130 km/h.

- Remarkable environmental gains: CO₂ savings of 94% compared to conventional steel constructions.

- Economic advantages: more ecological and cost-efficient than conventional steel construction.

- Material efficiency: Achieved a 2% reduction in overall material usage for the steel construction.

These impressive results aren’t merely data—they symbolize a clear message: ecological responsibility can, and indeed should, align seamlessly with economic benefit.

Vision for a Sustainable Future

Dimitri’s first successful structure isn’t an endpoint but rather an exciting beginning. Inspired by his initial success, Dimitri is determined to make reused rails a standard building material. He aims to create systematic applications, working closely with industry partners to generate local value, supporting railway infrastructure financially, and promoting social change by redefining perceptions of “used materials.” This project, though initially tagged “never build,” is now the cornerstone of a larger vision: a world where sustainability isn’t optional but integral to

architectural practice. Dimitri Durst’s story proves that innovative thinking, resilience, and determination can turn even decommissioned rails into valuable resources, setting a compelling example for sustainable construction worldwide.